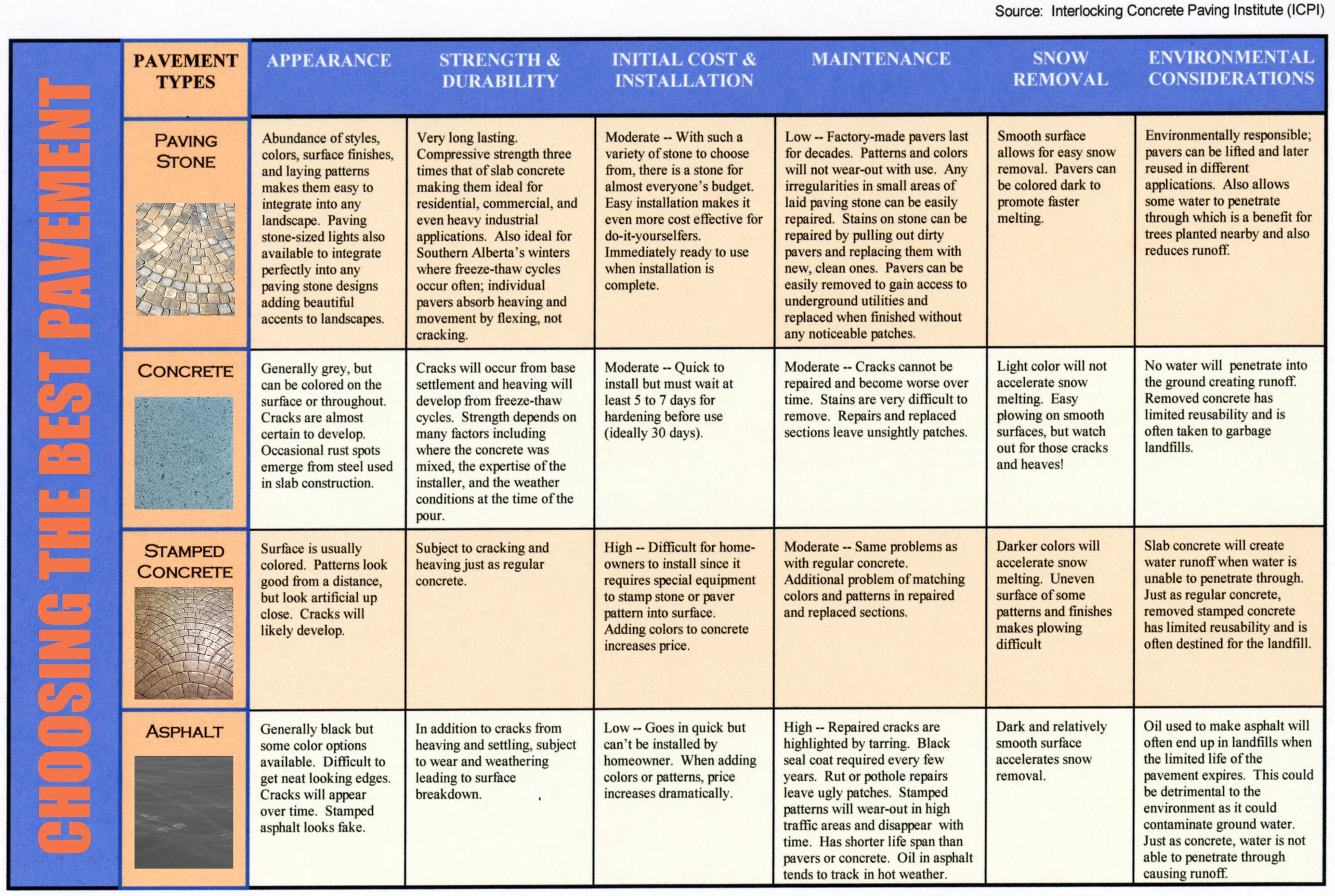

Comparing Paving Stone vs. Other Pavement

/Whether it be for a driveway, patio or sidewalk, when it comes to installing a paved surface in and around your yard, there are many different types of pavement to choose from.

With every choice come pros and cons to consider, but, after the comparisons have been made, paving stone is sure to be your superior choice. Here’s a few reasons why:

Appearance

There’s a reason why so many of those car beauty shots done by ad companies feature a vehicle beautifully situated on a paving stone driveway or cobble-stone street. Paving stone just looks better than your standard concrete slab or asphalt-paved road, thus enhancing the look of the product in the ad. The same will hold true in your yard.

Paving stone’s timeless, classy, and interesting look will work well in virtually every landscape since there are so many shapes and colours available to choose from. Doing a contemporary landscape? Large, rectilinear slabs in muted tones work beautifully! On the other end of the spectrum, tumbled cobble stones laid in flowing curves are excellent for cottage garden-style landscapes.

Just like lipstick on a pig, concrete and asphalt can be dressed up with the addition of colours and stamped patterns to resemble paving stone. However, with time and upon closer inspection, it is clear that they are mere impostors. Not to say that paving stone doesn’t like to masquerade on occasion as well! There are pavers available that resemble the look of wood or natural stone with the advantage of product longevity and/or cost savings when compared to the original.

Landscape lighting can be more easily integrated into hardscapes with the use of paving stone versus poured, slab concrete or asphalt. There are lights available that come in the exact dimensions as some standard pavers. Or small but powerful LED lights can be drilled directly into the paving stone to fit any style.

No matter what type of pavement you decide on, though, the appearance and longevity of the finished product will depend on the quality of the base preparation and product installation.

Strength & Durability

Driving around a city or town, it is quite evident that poured concrete and asphalt are the most common types of pavement, but it’s not due to the lack of paving stone’s suitability for our harsh southern Alberta climate.

As long as the proper base installation is done, paving stone will be more than suitable for pedestrian and vehicular traffic. Even many airport tarmacs and harbour-fronts use pavers! In fact, paving stone has a unique characteristic that actually makes it more suitable for the common freeze-thaw cycles that we encounter.

Unlike large, monolithic, rigid concrete slabs that will crack and heave, multifarious paving stone actually have the ability to flex with the inevitable, natural shifting that will occur between the cold temperatures of winter and the spring thaw.

Paving stone also has the advantage that it is produced in the controlled environment of a factory. Although proper base installation for all types of pavement is done so at the mercy of the weather, moisture and extreme temperatures during concrete and asphalt installation can compromise the quality of the end product unlike factory-made paving stone which also have a compressive strength three times greater than poured concrete.

As previously stated, both poured concrete and asphalt can resemble paving stone when patterns or colours are added. However, wear-and-tear will eventually reveal them for what they truly are! Paving stone will maintain their patterns and colours, features that make them so desirable, throughout their lifetime.

Initial Cost & Installation

The cost of installing any type of pavement depends on many factors, including the quality of the installation and products used. However, when comparing paving stone to regular poured concrete or asphalt, it most often will have a higher initial cost due to the labour-intensive nature of the installation.

There are a number of things that can be done to reduce costs that are unique to paving stone, though. Because there are so many types of pavers to choose from, there will be a stone suitable for almost every budget. Even previously-used paving stone could be installed at a fraction of the cost without compromising the strength and durability of the final product.

At first glance, paving stone appears to be a bit more expensive than regular concrete or asphalt, but when colours or stamped patterns are added to those types of pavement, the price will be quite comparable to paving stone. Also consider that you must often pay for a minimum amount of concrete or asphalt whether it’s used or not!

The time-sensitive nature of installing poured concrete and asphalt make them more difficult for a DIY customer to take on the job themselves. Paving stone installation is much more DIY-friendly as it can be more easily done whenever time allows, which can reduce the end cost of installation quite dramatically.

Lastly, when the paving stone installation is complete, it can be used immediately, unlike newly-poured concrete which needs at least a week, if not longer, to cure and be usable.

Maintenance

Although the initial cost of paving stone might be slightly more than poured concrete or asphalt, maintenance afterward will be simpler and cheaper with paving stone.

You need only to look as far as the cobblestone streets of Europe to see the lasting elegance of pavers. The factory-made bricks will most often last decades if not a lifetime, and their patterns will not wear out over time, unlike their stamped competitors.

Areas laid in paving stone consist of many individual bricks placed together to form a whole. Its flexible characteristic gives it an advantage compared to the monolithic nature of concrete or asphalt slabs that will crack and heave over time as the ground beneath moves.

With paving stone, when repairs need to be done, or if access below the surface is needed, it’s a simple matter of removing the pavers in question, repairing the base, then replacing the paving stone. This becomes a much larger job when whole sections of concrete or asphalt need to be removed then patched again after the repairs are complete. Not only will a paving stone repair be much cheaper, it will also be nearly unnoticeable when complete. The same can not be said for the distinct patch job done on the other types of pavement that will be noticeable for the life of the project.

With the addition of sealers and polymeric joint sand for paving stone, the common problem of weeds growing in the cracks is greatly reduced. Keep in mind, though, that even cracked concrete or asphalt will exhibit this characteristic too!

Snow Removal / Traction

Although there may be particular styles of paving stone that would not be as advisable to use where snow clearing is a concern, most paving stone feature chamfered or rounded edges allowing a snow shovel to glide over effortlessly. People often mistakenly assume that poured concrete and asphalt is easier to remove snow from than paving stone. Ultimately, though, that depends on the installation of the pavement. Just as heaved paving stone may be difficult to clean, so is cracked and heaved concrete.

The greater density of the factory-made pavers make them less susceptible to spalling and cracking as a result of chemical ice-melt products. Their surfaces also exceed slip tests and are generally less slippery than their competitors. Paving stone and slabs laid in dark colours will also promote quicker ice melt by the sun.

Environmental Considerations

The semi-permeable nature of paving stone has been explored and expanded upon over the years. New types of paving stone called Permeable Pavers are quite common now. These pavers actually encourage infiltration of rainwater to return the water to a natural water table while also being naturally filtered through the different levels of base material. Conversely, the impermeable nature of slab concrete and asphalt will promote runoff which could lead to localized flooding in the case of heavy rains. The runoff also often carries common toxins such as oil and other vehicle fluids which could end up in rivers and lakes.

The reusable nature of paving stone is probably its largest contribution to environmental stewardship. Paving stone can be removed and relayed, whether it’s in the short term as in the case of accessing utilities, or used again years down the line on a different project altogether. Unfortunately, slab concrete and asphalt can not removed and reused as easily and often end up in landfills. In some instances, they will be later crushed and reused as road base but, with reinforcing steel often embedded in the concrete and asphalt containing bitumen oil, recycling and reusability becomes more complicated.

Imagine those famous pedestrian streets or European squares without paving stone. They wouldn’t have nearly the same amount of charm.

Not only will paving stone add interest to your yard, it is extremely durable and strong, easy to maintain, and environmentally friendly.

Although the initial cost of installation may be marginally higher than regular concrete or asphalt, the low cost of maintenance and the added value to your home will make it an investment in your property.